Μετάφραση και ανάλυση λέξεων από την τεχνητή νοημοσύνη ChatGPT

Σε αυτήν τη σελίδα μπορείτε να λάβετε μια λεπτομερή ανάλυση μιας λέξης ή μιας φράσης, η οποία δημιουργήθηκε χρησιμοποιώντας το ChatGPT, την καλύτερη τεχνολογία τεχνητής νοημοσύνης μέχρι σήμερα:

- πώς χρησιμοποιείται η λέξη

- συχνότητα χρήσης

- χρησιμοποιείται πιο συχνά στον προφορικό ή γραπτό λόγο

- επιλογές μετάφρασης λέξεων

- παραδείγματα χρήσης (πολλές φράσεις με μετάφραση)

- ετυμολογία

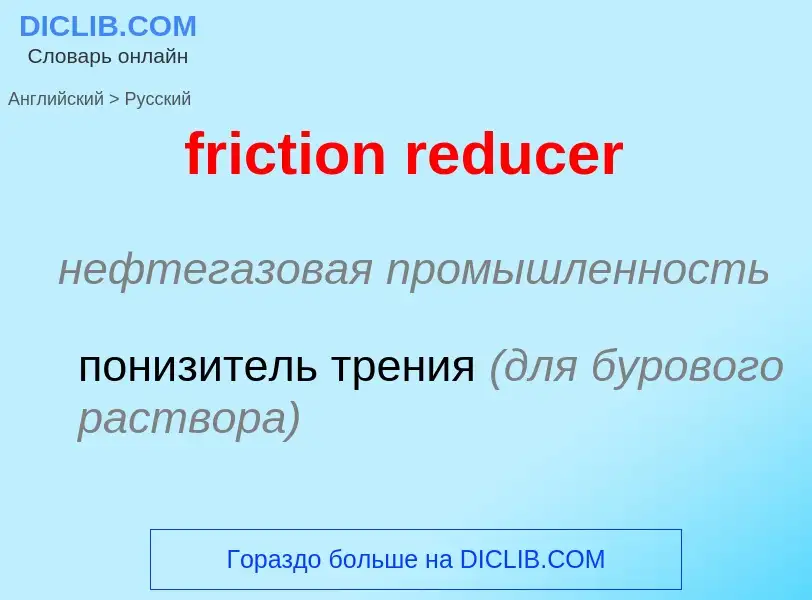

friction reducer - translation to ρωσικά

нефтегазовая промышленность

понизитель трения (для бурового раствора)

общая лексика

угол трения

Ορισμός

Βικιπαίδεια

A friction drive or friction engine is a type of transmission that utilises two wheels in the transmission to transfer power from the engine to the driving wheels. The system is naturally a continuously variable transmission; by moving the two disks' positions, the output ratio changes continually. Although once used in early automobiles, today the system is most commonly used on scooters, mainly go-peds, in place of a chain and gear system. It is mechanically identical to a ball-and-disk integrator, but intended to handle higher torque levels.

The system consists of two disks, normally metal, set at right angles to each other. One disk is connected to the engine, the other to the load. The load disk is positioned so that its outer rim is pressed against the driven disk, and normally has some sort of high-friction surface applied to the outer rim to improve torque transfer. In early systems, paper and leather was often used for this surface. One of the disks, normally the load side, is mounted on a shaft that allows it to be moved in relation to the driven disk, allowing it to move from a position at the center of the driven disk to its outer radius. Moving the load disk along this shaft changes the ratio of input to output speed; when the load disk is at the center the output is zero, when it is at the outer rim, it is the ratio of the radius of the two disks.

While mechanically simple and providing a variable transmission that requires no clutch, there are a number of problems with the design that limit its use. The first is that the amount of torque that can be transferred is a function of the contact patch between the two disks, and thus a function of the width of the load disk. Increasing this width improves torque handling, but then runs into a second problem. As the "gear ratio" is a function of the distance from the center of the driven disk, any finite thickness on the driven disk means the inner and outer edges are being driven at different speeds. This causes considerable friction on the bearing surface, wearing it out and giving off significant amounts of heat. This results in a sweet spot that limits it to certain low-torque roles.

![Lambert automobile]] from 1906 with the friction drive revealed. The large disk closer to the top is connected to the engine, the smaller one drives the wheels via chains (missing here). Lambert automobile]] from 1906 with the friction drive revealed. The large disk closer to the top is connected to the engine, the smaller one drives the wheels via chains (missing here).](https://commons.wikimedia.org/wiki/Special:FilePath/1906 Lambert 2-cylinder chassis.png?width=200)

![Figure 1: Simulated blocks with [[fractal]] rough surfaces, exhibiting static frictional interactions<ref name="statfric" /> Figure 1: Simulated blocks with [[fractal]] rough surfaces, exhibiting static frictional interactions<ref name="statfric" />](https://commons.wikimedia.org/wiki/Special:FilePath/Friction between surfaces.jpg?width=200)